news

FAQ – Professional metal 3D printers with selective metal powder bed fusion laser.

During the printing process, is the material completely melted? Is any porosity present inside or on the surface? The metal components printed with LMF (Laser Metal Fusion) technology generally have a rough surface but very high (close to 100%) densities,...

Technology – LMF 3D printer

Patented Tilting Coater Metal 3D printing with powder-bed based technologies involves the addition of material through unidirectional or bidirectional coating systems, "coaters". The "tilting coater" patented by SISMA, supplied with every 3D printer of...

RFX: the largest experiment in the world for the study of the confinement of nuclear fusion plasmas.

SISMA collaborates in the MIAIVO project – Innovative Mechanics and Integrated Additive: VenetO from research to opportunities in the current and future market – to analyze the technological feasibility of a set of modifications to the RFX-mod2 experimental machine.

A journey of growth over 60 years.

A journey of growth over 60 years. Here at SISMA we have been designing and manufacturing high-precision machinery and laser systems since 1961. Our path has been a transversal experience undertaken in mechanics, in software management, and in...

Manual laser welders for dental laboratories

LM-D, manual laser welding system.StableLM-D incorporates the Smart Spot technology for a repeatable welding process ensuring a wide depth of field and a stable laser firing already from the first pulses.ComfortableThe new ergonomic design and low noise...

DFS (Dynamic Focus Shift), perfect laser markings also on non-flat surfaces.

SISMA DFS consists of a third optical axis that can be integrated in SISMA laser markers (selected models) allowing perfect execution of markings on non-flat surfaces or on flat surfaces with differences in Z (height), within a certain interval depending on the focal...

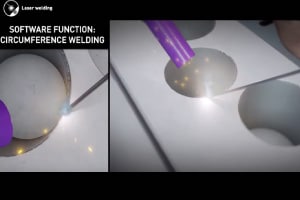

TRACKED ROUTES software functionalities, for molds repairing in assisted mode.

TRACKED ROUTES software functionalities, for molds repairing in assisted mode. TRACKED ROUTES allow to perform a welding process in semi-manual guided mode. These software features can be activated directly from the user interface of the SISMA...

POWER RAMP, optimized welding at critical points.

POWER RAMP, optimized welding at critical points. POWER RAMP is a software function developed by SISMA that affects the laser welding process by optimizing its performance, specifically at two critical points: the start and end of the welding process. By modulating...

BSP PICO – Laser marking and engraving system with ultrashort laser source for industrial field

BSP PICO is a laser marking and engraving machine which uses a picosecond laser source Picosecond laser sourceThis type of source generates pulses lasting only a few picosecond with peak intensities so high that non-linear/multiphoton absorption...

BSP PICO – Laser marking and engraving system with ultrashort laser source for jewelry field

Ultrashort laser source This type of ultrashort laser source generates pulses lasting only a few picoseconds with peak intensities so high that non-linear/ multiphoton absorption takes place, designed for high aesthetic quality...