Case study

2D and 3D laser marking, engraving and texturing solutions

Meccanica Tecnica s.r.l. is a leader company in precison mechanical engineering. The company offers contractor service, so it needs to mark or engrave with laser technology in many different situations and areas:

• Electronics: quick and small markings.

• Medical: markings resistant to many cleanings and sterilazation cycles.

• Aerospace: markings that do not alter the characteristics of the material.

• Automotive: marking of serial numbers, data plates, backlit components.

• Mechanical: endless 2D and 3D marking and engraving applications.

• Promotional: fast processing of small batches and single piece.

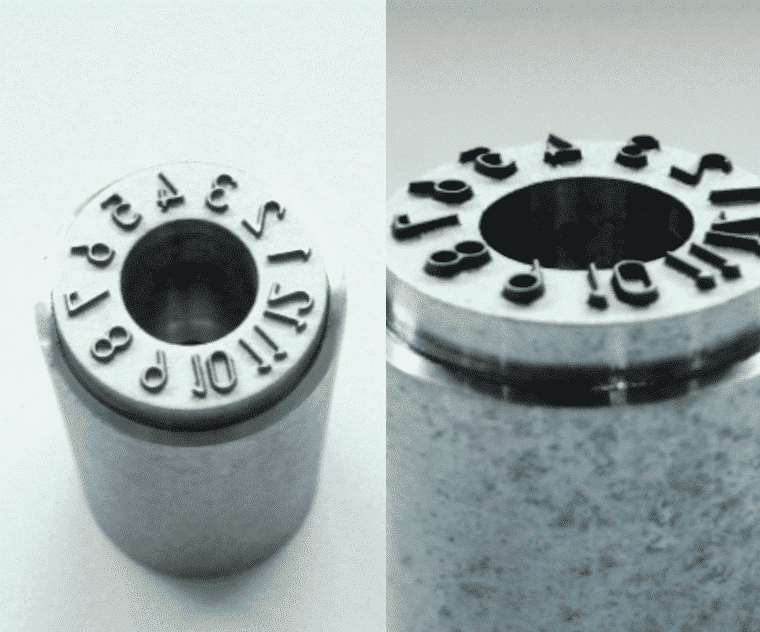

In these various fields, very different types of engraving and marking are required:

• Blackening

• Paint removal

• Marking on flat or curved surfaces

• Engraving 2D-3D on flat or curved surfaces

• Texture on flat or curved surfaces

• Surfaces treatment and color marking

To deal with such diverse situations, including the possibility of working on large objects, the choice fell on Sisma BSS-3D laser marking machine.

It’s an extremely versatile machine with a number of features that have made it a winning choice:

• Working area for objects up to 700 x 400 x 380 mm

• Possibility of marking, engraving 2D-3D and micro cutting

• High positioning accuracy and repeatability

• Up to 5 axes machine

• Robot available

Meccanica Tecnica Srl, based in Bastiglia (Modena), has more than 50 years of experience in the field of plastic and die-casting molds, equipments and precision mechanical construction.

An ISO 9001-certified company, it makes use of modern, high-tech machines; it has an established professionalism that enables it to propose sophisticated technical solutions.

It is a recognized reference point for precision machining (EDM, laser welding and marking, micro-drilling, 5-axis CNC milling) and has state-of-the-art 3D printers for metal, plastic and resin.

Curious about all Sisma’s marking and engraving applications? Contact us and we will be happy to answer all your questions.