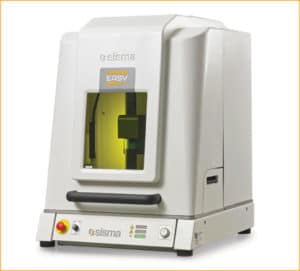

Modular solutions for 2D-3D laser engraving and texturing

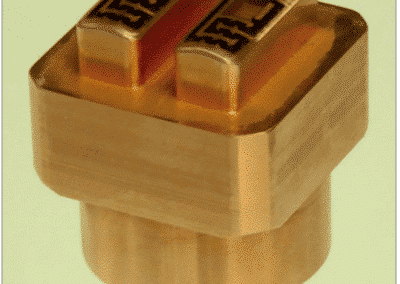

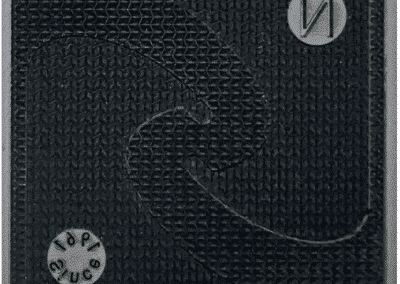

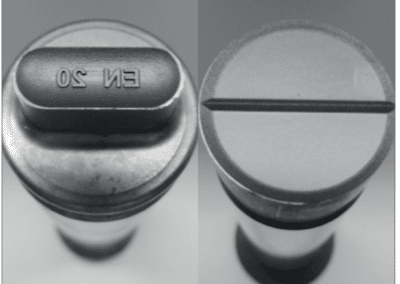

Find out how SISMA made it easier for people to create laser engravings and textures on punches, electrodes and other applications that require 2D-3D texture laser processes.

ENGRAVING PROCESSES

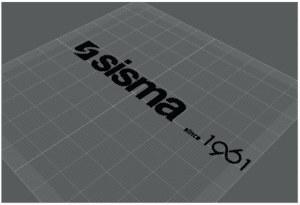

2D engraving on 2D surface

Two-dimensional

engraving on a flat surface.

File: SVG.

The depth is managed

from Parameter by the user.

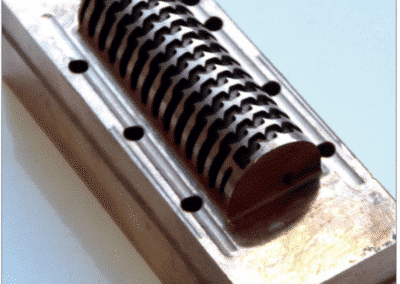

2D engraving on 3D surface*

Two-dimensional engraving on a non-planar surface.

File: SVG on OBJ.

The depth is managed from Parameters by the user.

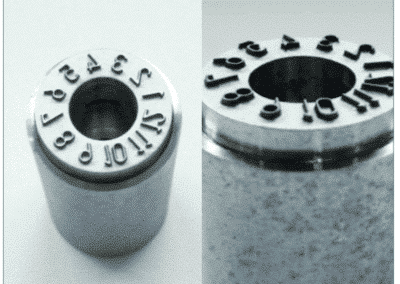

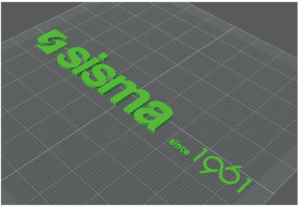

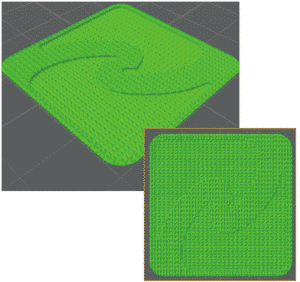

3D engraving on 2D surface

Three-dimensional engraving on

a flat surface.

File: STL.

The depth information is given by the stl file.

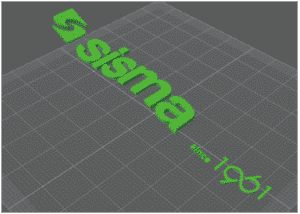

3D engraving on 3D surface

Three-dimensional engraving on a non-planar surface.

File: STL.

The depth information is given by the stl file.

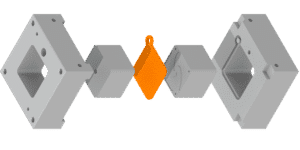

*Dynamic Focus Shifter: such optical component, which allows to make continuous engravings on 3D surfaces, is also available upon request.

SOFTWARE

SISMA SLC3 : the easiest way to make your engraving or textures.

The engraving process ( with depth ≥ 0,1 mm) takes into consideration the amount of material removed for each laser pass. Once the material is characterized, the system automatically defines the Z-steps necessary to obtain a perfect engraving in terms of dimensions and finishing. In the case of 3D files (.STL) the depth information is already available in the graphic.

SLC³ allows:

• easier and faster tuning and testing;

• slicing of the STL file;

• automatic generation of the layer number;

• flexible cleaning passes management.

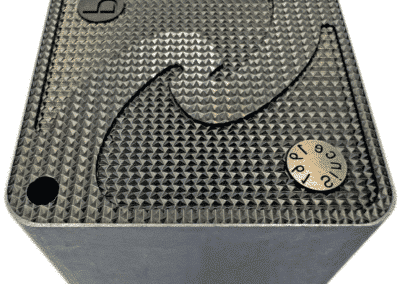

The Texture mode is a variant that produces the slicing from a grayscale file;

The Texture mode is a variant that produces the slicing from a grayscale file;

with SLC³ it is possible to draw a working area and fill it using png, bmp, jpg

and tiff files. The colour white (brightness = 240) means no laser working,

whereas the colour black (brightness = 0) will be assigned to the set depth.

This is an easy way to engrave companies logo or to apply a pattern on a

surface.

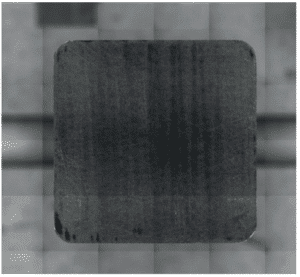

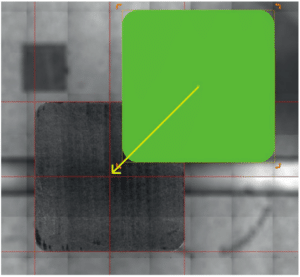

VISION SYSTEM

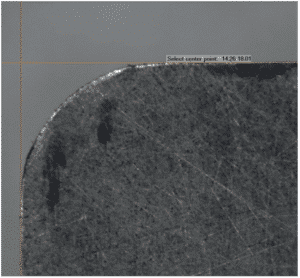

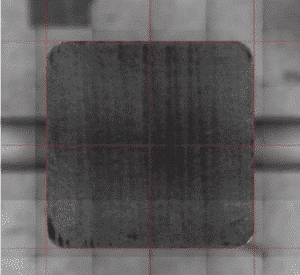

SISMA CVS (Coaxial Vision System): the easiest and most precise way to center your piece.

With the new Guide lines feature, centering becomes simple and fast: after positioning the relevant lines at the edges of the object is possible to obtain, with one click the median position. The snap on the grid allows to place the file at the preferred control points.

The system is characterized by:

• simplified verification and realignment function (with possible correction) between camera and laser (<1 min);

• high accuracy (0.02 mm);

• simplified procedures for camera calibration and automatic focal mapping (under patent protection).

CVS advantages:

• High precision and repetitive centering process;

• Possibility to avoid jigs or fixtures;

• Possibility to re-work on the same piece to reach required depth or finishing;

• Live view of the pieces with possibility for manual or automatic (pattern matching) file positioning.

EASY MOLD is available on:

APPLICATIONS