Discover the Sisma laser systems for molds and molding

Laser systems find many applications in mold making and molding processes of plastic or metal materials.

One of the most common uses of laser welding is in the repair and maintenance of molds by material filling: it is a semi-automatic process in which the operator’s skill is supported by a very stable, repeatable technology and software functionality that facilitates processing.

In addition, the laser has a very localised thermal impact, therefore minimal, leaving the mechanical characteristics of the material unchanged and minimising post-processing activities.

This is an example of how SWA is specially designed to perform modifications and repairs to molds damaged by wear or use: the repair of an alluminum bronze + nickel mold for bottle forming.

Molds used in the production of glass packaging, shape the product by contacting with high temperature molten glass in the air, therefore they are exposed to mechanical stresses and thermal cycles. Damages on the mold surfaces with these effects limit the service life of the molds and deteriorate the product quality.

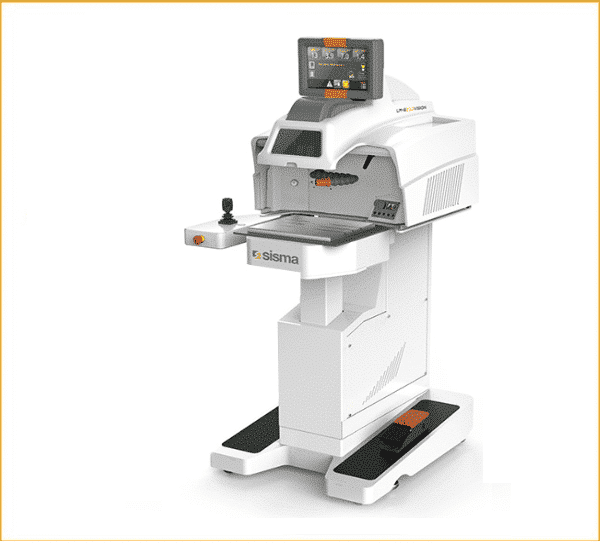

Sisma offers an extended range of laser welding systems , from simpler and compact models such as LM-B for welding on small molds and inserts, to SWT versions dedicated to machining on medium-sized parts, to the SWA series that allows maximum flexibility and ease of use even on large molds.

The laser can be used not only for mold repair and maintenance, but also for repairing parts produced by die casting (again with material input), or for welding mechanical parts in various areas.

In these cases, it is extremely expensive to replace the mold, so it is certainly useful to evaluate the possibility of repairing it.

To do this, however, it is not convenient to rely on traditional welding methods, because the materials in which the molds are made - as well as the delicacy of the intervention - make it difficult to intervene in this way. This is where the laser comes to the aid of the industry, offering a quick, precise and efficient solution to the problem.

Our system laser solutions for molds and molding

GET STARTED